Liquid Molding Monthly

Unleashing the Power of Best Resin Coating in Global Manufacturing Revolution

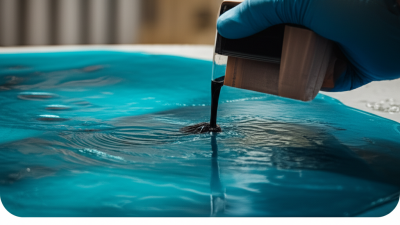

In the ever-evolving landscape of global manufacturing, the 2025 industry technology trends reveal a significant shift towards advanced materials, particularly in the realm of resin coatings. According to a recent report by MarketsandMarkets, the global resin coating market is projected to reach USD 17.4 billion by 2025, growing at a CAGR of 6.4%. This growth underscores the increasing adoption of resin coatings across various sectors, driven by their superior protective properties and environmental resilience. As manufacturers seek to enhance product durability and performance, the implementation of advanced resin coating technologies is becoming a cornerstone strategy. This blog will explore the transformative potential of resin coatings, highlighting top strategies to harness this innovation for competitive advantage in the manufacturing revolution.

The Rising Demand for Advanced Resin Coatings in Global Manufacturing

The demand for advanced resin coatings in global manufacturing is witnessing an unprecedented rise, driven by their versatile properties and applications across various industries. According to a recent report by MarketsandMarkets, the global resin coating market is projected to reach USD 56.25 billion by 2025, growing at a CAGR of 6.5% from 2020 to 2025. This surge is primarily fueled by the increasing emphasis on durability and aesthetic appeal in consumer products, as well as the need for sustainable solutions that minimize environmental impact.

Moreover, the automotive and aerospace sectors are among the leading adopters of advanced resin coatings. In 2023, the automotive industry alone accounted for approximately 45% of the total resin coatings market share, as manufacturers increasingly utilize these coatings for their superior protective capabilities and ability to enhance performance under harsh conditions. The growing trend towards electrification and lightweight materials in vehicles further amplifies the demand for specialized resin solutions that meet stringent regulatory standards while improving overall efficiency. As manufacturers strive to innovate and differentiate their offerings, advanced resin coatings will undoubtedly play a pivotal role in shaping the future of global manufacturing.

Unleashing the Power of Best Resin Coating in Global Manufacturing Revolution

| Application Sector | Resin Type | Market Demand (2023) | Growth Rate (2023-2028) | Key Properties |

|---|---|---|---|---|

| Automotive | Epoxy Resin | $1.5 Billion | 7.5% | High strength, corrosion resistance |

| Electronics | Polyurethane Resin | $750 Million | 6% | Flexibility, thermal stability |

| Construction | Acrylic Resin | $1.2 Billion | 8% | UV stability, ease of application |

| Marine | Vinyl Ester Resin | $600 Million | 5% | Chemical resistance, low moisture absorption |

| Aerospace | Phenolic Resin | $800 Million | 6.5% | Fire resistance, dimensional stability |

Key Benefits of Using Resin Coatings: Durability and Performance Metrics

In the rapidly evolving landscape of global manufacturing, the adoption of resin coatings has emerged as a game-changer, offering a blend of durability and performance that traditional coatings often struggle to match. Resin coatings provide a superior shield against environmental factors such as moisture, UV light, and chemical exposure, ensuring that products maintain their integrity and appearance over time. Industries have witnessed a marked improvement in product lifespan and reduced maintenance costs, empowering manufacturers to focus on innovation rather than repairs.

**Tip:** When selecting a resin coating, consider the specific environmental challenges your product will face. This targeted approach can significantly enhance durability and long-term performance.

Moreover, performance metrics suggest that resin coatings can enhance friction resistance and reduce wear and tear on mechanical components. This not only improves efficiency but also contributes to higher overall productivity within manufacturing processes. By balancing flexibility with strength, resin coatings can adapt to various applications across industries, from automotive to electronics.

**Tip:** Always conduct thorough testing to determine the ideal resin formula for your project, as different applications may require unique properties to optimize performance and efficacy.

Market Trends: The Expansion of the Global Resin Coating Industry

The global resin coating industry is experiencing a dynamic expansion, driven by advancements in technology and increasing demand across various sectors. As manufacturers worldwide seek durable, protective solutions for their products, resin coatings are becoming a preferred choice due to their superior performance characteristics. These coatings offer resistance to chemicals, moisture, and extreme temperatures, making them an ideal solution for industries ranging from automotive to electronics. The surge in infrastructural developments and the rise of the construction sector further bolster the demand for high-quality resin coatings.

Market trends indicate a growing inclination towards eco-friendly and sustainable resin solutions, as manufacturers prioritize environmental impact alongside performance. Innovations in bio-based resins are gaining traction, appealing to companies looking to reduce their carbon footprint. Additionally, the digital transformation of production processes is enhancing the customization capabilities of resin coatings, allowing manufacturers to meet specific client specifications efficiently. As industries adapt to these evolving trends, the global resin coating market is set to continue its impressive growth trajectory, redefining standards in quality and sustainability.

Global Resin Coating Industry Trends (2022-2026)

The chart above illustrates the projected growth of the global resin coating market from 2022 to 2026, showcasing an increasing trend in market value driven by advancements in manufacturing processes and applications.

China's Role in Resin Coating Innovation and Export Growth

China has emerged as a global leader in resin coating innovation, significantly influencing both domestic and international markets. According to a report by Research and Markets, the global resin coatings market is projected to reach $30 billion by 2027, with China accounting for a substantial portion of this growth. This surge can be attributed to China’s robust manufacturing sector and its investment in advanced technologies. The country has focused on developing eco-friendly resin solutions, aligning with global sustainability trends and regulations, which has enhanced its competitive edge.

Furthermore, China's export growth in resin coatings has been remarkable. The China Coating Industry Association reported that in the past five years, exports of resin coatings have increased by nearly 15% annually. Major markets include the United States, Europe, and emerging economies in Asia, driven by a rising demand for high-performance coatings in automotive, construction, and electronics sectors. As Chinese manufacturers continue to innovate, they are not only catering to current market needs but are also setting trends that improve product performance and environmental compliance, positioning China at the forefront of the resin coating revolution.

Sustainability in Manufacturing: The Role of Eco-Friendly Resin Coatings

As the manufacturing sector faces increasing scrutiny over environmental impact, eco-friendly resin coatings are emerging as a cornerstone of sustainable practices. The use of lignin-based epoxy resins, for example, is gaining momentum due to their renewable nature and lower chemical emissions compared to traditional counterparts. By leveraging these innovative materials, manufacturers can significantly reduce their ecological footprint while still achieving high-performance standards in their coatings. This shift not only meets regulatory demands but also aligns with consumer preferences for greener products.

The global market for coatings, particularly in emerging economies like India, reflects a growing commitment to sustainability. With the India Paints & Coatings Market projected to expand from USD 15.78 billion in 2024 to USD 27.93 billion by 2030, the adoption of eco-friendly resin options is pivotal. Industries are increasingly recognizing the importance of sustainable choices in not only enhancing brand reputation but also ensuring long-term viability in a competitive market. As businesses continue to invest in green technologies, the role of resin coatings in fostering sustainable manufacturing practices will undoubtedly play a crucial role in shaping the future of the industry.

100% Mercury Free

All of Hapco's formulations are completely free of Mercury.

50 Year Track Record

Hapco has been in business for over 50 years!

*NOTICE* Hapco will be will be closed on Monday, May 26th, in observance of Memorial Day. |

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |