Liquid Molding Monthly

Essential Tips for Choosing the Right Damper Actuator?

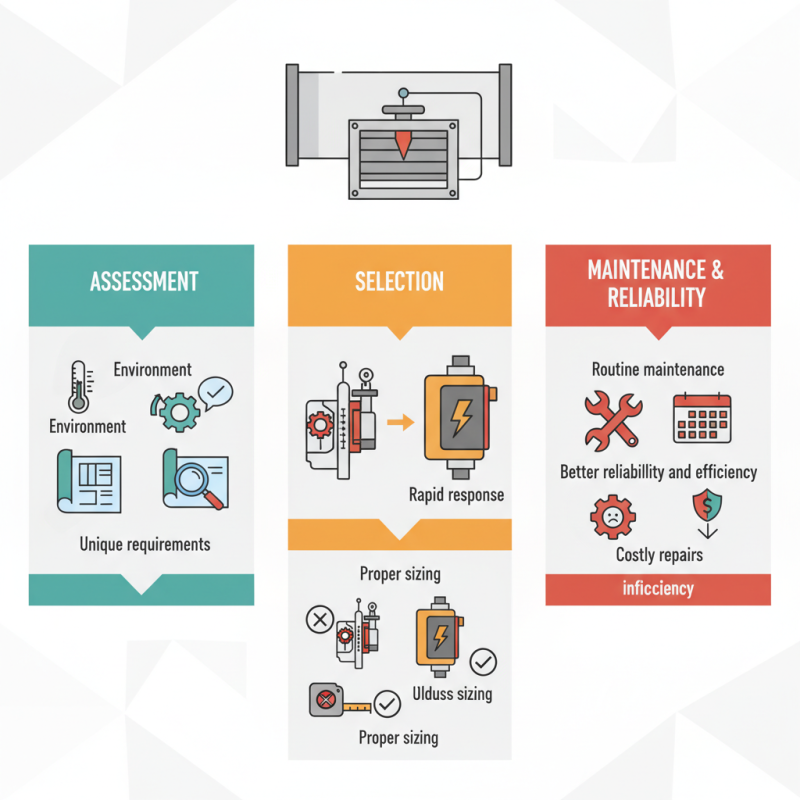

Choosing the right Damper Actuator is crucial in building HVAC systems. Expert John Smith, a renowned specialist in the field, once stated, “The wrong actuator can lead to inefficiency and costly repairs.” This highlights the importance of making an informed choice.

Understanding the specifics of damper actuators is vital. There are various types, each with unique capabilities. Some are designed for precise control, while others provide rapid response. This means assessing your unique requirements is essential. You need to consider factors like the environment and load demands.

Moreover, often overlooked aspects can lead to issues. For instance, improper sizing of a damper actuator can result in operational failures. Additionally, routine maintenance is necessary to avoid long-term problems. Neglect can lead to performance drops. Remember, investing time in the selection process can ensure better reliability and efficiency in the long run.

Understanding the Basics of Damper Actuators

When selecting a damper actuator, understanding its fundamentals is crucial. A damper actuator regulates airflow by controlling the position of a damper. These devices come in various types, including electric and pneumatic options. Reports indicate that about 35% of energy consumption in buildings is related to HVAC systems. This emphasizes the importance of an efficient actuator.

Tip: Evaluate your system's specific requirements before choosing an actuator. Performance metrics such as response time and torque ratings should align with your building’s demands. Many users overlook these specifications, which can lead to inefficiencies.

The environmental impact of damper actuators cannot be ignored. According to industry data, poorly selected actuators can increase energy usage by 25%. This not only elevates costs but also impacts sustainability goals.

Tip: Ensure compatibility with your existing HVAC components. Misalignment can cause operational issues. Sometimes, a more expensive actuator may prove cost-effective in the long run due to better reliability and efficiency.

Essential Tips for Choosing the Right Damper Actuator

| Criteria | Considerations | Examples |

|---|---|---|

| Type of Actuator | Choose between electric, pneumatic, or hydraulic actuators based on application. | Electric: 24V, Pneumatic: 3-15 psi |

| Performance Requirements | Evaluate speed, torque, and precision needed for your system. | Speed: 1-5 sec for full stroke, Torque: up to 100Nm |

| Control Method | Determine if you need open-loop or closed-loop control. | Open-loop: basic position control; Closed-loop: feedback systems |

| Environment Conditions | Assess exposure to temperature, humidity, and contaminants. | Operating temp: -10°C to 50°C, IP65 rated against dust and water |

| Installation and Maintenance | Consider ease of installation, accessibility for maintenance. | Plug-and-play models; maintenance-free options available |

Key Factors to Consider When Choosing a Damper Actuator

Choosing the right damper actuator requires careful consideration of several key factors. First, the actuator type is crucial. There are electric, pneumatic, and hydraulic options. Each type has unique advantages and limitations. Electric actuators are often simpler to install. However, they may require more maintenance and might not perform well in extreme temperatures.

Another important factor is the actuator’s torque. It should match the damper size and application requirements. Too much torque can wear out the system. Conversely, too little torque might cause malfunction. Always check the specifications and ensure that you have the right match for your needs.

Also, consider the environmental conditions where the actuator will be installed. Dust, moisture, and temperature can all affect performance. Actuators made for harsh environments may be necessary. However, they often cost more and might not be readily available. Reflect on your long-term needs versus immediate costs. The right choice can significantly impact efficiency and reliability in the long run.

Essential Tips for Choosing the Right Damper Actuator

Types of Damper Actuators and Their Applications

When selecting the right damper actuator, it’s crucial to understand the various types available. This knowledge enables better operational efficiency. Broadly, we categorize actuators into two main types: electric and pneumatic. Electric actuators are known for their precise control and ease of integration. In contrast, pneumatic actuators rely on air pressure, making them suitable for environments requiring rapid actuation. According to a recent industry report, electric actuators now account for 60% of market demand due to their energy efficiency.

Different applications necessitate distinct features. For instance, fire dampers require actuators that can withstand extreme temperatures. On the other hand, HVAC systems often favor actuators that allow for smooth, continuous adjustment. A study from the International Society of Automation found that poorly chosen actuators can lead to energy inefficiencies of up to 30%. Therefore, reflecting on environmental needs and performance metrics is essential for making informed choices.

Price alone should not dictate the selection. Understanding operational requirements and maintenance demands is key. Working with the wrong actuator can lead to operational failures. The interplay between type, application, and environment must be carefully considered. It's easy to overlook these factors amidst many choices. However, doing so may result in costly mistakes.

Evaluating Performance Specifications for Damper Actuators

When evaluating performance specifications for damper actuators, it's crucial to focus on key criteria. Consider the torque output, speed, and response time. A robust actuator typically offers higher torque and faster reaction to changes. Data suggests that actuators with a torque range of 20 to 60 Nm often perform best in commercial applications. These specifications ensure they can handle varying airflow rates effectively.

Tips for selecting the right actuator include examining the load conditions. Know the specific duties or cycles the actuator will repeatedly perform. It's also vital to assess environmental factors, like temperature and humidity. Actuators that operate in harsh conditions may need extra protection, affecting performance and longevity.

Don't overlook compatibility with control systems. Some actuators integrate seamlessly with standard systems, while others may face limitations. Research shows that approximately 30% of installation issues stem from compatibility failures. Take the time to understand the entire mechanism before making your choice.

Ensuring Compatibility with HVAC Systems and Controls

When selecting a damper actuator, compatibility with HVAC systems is crucial. Research indicates that around 30% of HVAC system failures are linked to improper actuator selection. Factors such as torque capacity, control type, and response time must align with your system's specifications. If an actuator cannot deliver the necessary torque, it may lead to inadequate airflow and inefficient heating or cooling.

Equally important is the actuator’s communication with controls. Many modern systems utilize protocols like BACnet or Modbus. A mismatch can hinder system performance and increase energy costs. According to industry reports, up to 40% of energy is wasted due to inefficient control strategies. Checking compatibility with control systems is not just a precaution; it is essential for optimal operation.

Another consideration is the environmental conditions. Actuators must withstand temperature variations and humidity levels. Selecting an actuator suited for your environment minimizes maintenance issues. Some users overlook this aspect, leading to frequent replacements. Identifying the right specifications helps avoid these pitfalls because details matter in ensuring a cohesive HVAC setup.

Article Source:

100% Mercury Free

All of Hapco's formulations are completely free of Mercury.

50 Year Track Record

Hapco has been in business for over 50 years!

*NOTICE* Hapco will be will be closed on Monday, May 26th, in observance of Memorial Day. |

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |