Liquid Molding Monthly

5 Essential Tips for Choosing the Right Plastic Resin for Your Projects

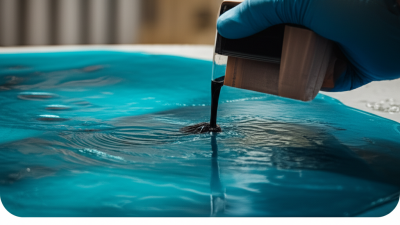

Choosing the right plastic resin for your projects is critical in ensuring durability, performance, and cost-effectiveness. According to a report by MarketsandMarkets, the global plastic resin market is expected to surpass $1 trillion by 2025, reflecting a growing demand across various industries, including automotive, packaging, and electronics. With a plethora of options available, selecting the appropriate plastic resin can be daunting, especially considering factors such as thermal stability, chemical resistance, and mechanical properties.

An industry study revealed that nearly 60% of engineers struggle with material selection due to inadequate understanding of resin characteristics. Thus, it is essential to grasp the fundamentals of plastic resins to make informed decisions that align with project requirements and performance expectations. This blog outlines five essential tips to guide you in selecting the right plastic resin, ensuring your projects meet both functional and economic goals.

Understanding Plastic Resins: Key Properties and Their Impact on Project Success

When selecting the appropriate plastic resin for your project, understanding the key properties of different resins is crucial for ensuring project success. Plastic resins, such as polycarbonate (PC), polyethylene (PE), and polypropylene (PP), each exhibit unique physical and chemical characteristics that influence their suitability for various applications. For instance, polycarbonate is renowned for its high impact resistance and optical clarity, making it ideal for protective gear and transparent applications. According to a report by MarketsandMarkets, the global polycarbonate market is projected to reach $18.2 billion by 2025, underscoring its importance in numerous industries.

Moreover, the thermal properties of plastic resins can significantly affect their performance. For example, polypropylene has a melting point of around 160°C, which allows it to be suitable for high-temperature applications, such as automotive components. In contrast, the softer nature of polyethylene makes it an excellent choice for products requiring flexibility, like packaging materials. Industry data indicates that demand for polyethylene is expected to grow by 4.5% annually, reflecting its versatility and essential role in various manufacturing processes. Thus, comprehensively evaluating the key properties of plastic resins is vital for choosing the right material that aligns with both functionality and project objectives.

5 Essential Tips for Choosing the Right Plastic Resin for Your Projects

| Property | Description | Impact on Project |

|---|---|---|

| Thermal Stability | Resistance to deformation at high temperatures | Critical for applications exposed to heat |

| Chemical Resistance | Ability to withstand corrosive substances | Essential for durability in harsh environments |

| Impact Resistance | Durability against sudden forces or shocks | Increases safety and longevity of the product |

| UV Stability | Resistance to degradation by ultraviolet light | Important for outdoor applications |

| Flexibility | Ability to bend without breaking | Allows for resilience in dynamic environments |

Analyzing the Cost-Effectiveness of Different Plastic Resins in Manufacturing

When selecting the right plastic resin for manufacturing processes, cost-effectiveness plays a pivotal role in ensuring project viability and competitiveness. High-performance plastics, characterized by their exceptional chemical stability, mechanical strength, and thermal resistance, present an attractive option for businesses aiming to optimize production costs without compromising quality. As industries evolve towards lightweight materials and more efficient production methods, the demand for these advanced plastics continues to grow, driven by their ability to provide significant long-term savings.

The global plastic additives market is projected to expand notably, with estimates suggesting an increase from $60.35 billion in 2024 to $98.5 billion by 2032. This growth can be attributed to the rising adoption of engineered plastics and innovative formulations that enhance the properties of base materials, allowing manufacturers to meet stringent performance requirements while keeping costs in check. As manufacturers increasingly explore new markets through trade agreements like CPTPP, the focus remains on sourcing high-performance resins that bring both economic and functional advantages to their projects.

Identifying Environmental Considerations in Selecting Sustainable Plastic Materials

When selecting sustainable plastic materials for your projects, it's essential to consider environmental impacts. With the biodegradable plastics market projected to grow from $9.5 billion in 2024 to $32.61 billion by 2031, understanding the eco-friendliness of the resins you choose is crucial. Consumers increasingly demand brands to respond to climate change concerns, with a significant 89% shifting toward sustainable products. This trend emphasizes the importance of identifying resins that meet sustainability standards.

One of the key tips for choosing the right plastic resin is to evaluate its life cycle. Consider how it is produced, used, and disposed of. Look for resins that offer certifications or are recognized for their low environmental footprint. Additionally, engage with suppliers who prioritize eco-friendly practices. By selecting materials that align with these values, you not only contribute to resource conservation but also resonate with a conscious consumer base.

Finally, keep an eye on the evolving regulations and market trends in sustainable packaging and plastics. Awareness of these factors can help you innovate and adapt your projects to meet changing demands, ensuring you remain competitive in a market that is increasingly leaning towards sustainability.

5 Essential Tips for Choosing the Right Plastic Resin for Your Projects

This chart displays the environmental impact of various plastic resins based on their recyclability, energy consumption during production, and biodegradability. The data helps in understanding which materials are more sustainable for projects.

Evaluating Performance Metrics: Strength, Durability, and Temperature Resistance of Resins

When selecting the appropriate plastic resin for your projects, understanding its performance metrics is crucial. Strength is the first key attribute to consider. Different resins exhibit varying levels of tensile strength, which determines their resistance to being pulled apart. For applications requiring heavy-duty performance, such as automotive or industrial components, high-strength resins like polycarbonate or nylon are ideal. Meanwhile, for lighter applications, materials like polystyrene may suffice.

Durability and temperature resistance are equally important factors. Durability refers to the resin's ability to withstand wear, pressure, or damage, making it essential for long-lasting products. Resins such as polyethylene or polypropylene often provide excellent durability for everyday items. On the other hand, temperature resistance is vital for projects exposed to extreme conditions. Materials like phenolic resins can endure high temperatures, ensuring that they maintain their integrity in harsh environments. By carefully evaluating these performance metrics—strength, durability, and temperature resistance—you can select the right plastic resin that aligns perfectly with your project's specific requirements.

Navigating Supplier Options: Ensuring Quality and Consistency in Resin Procurement

When navigating the landscape of plastic resin procurement, it’s crucial to prioritize quality and consistency in your supplier options. The first step in this journey is conducting thorough research. Look for suppliers with a solid reputation in the industry, as well as positive customer reviews. Certifications and compliance with industry standards can also serve as indicators of reliability. It’s beneficial to request samples from potential suppliers to evaluate both material properties and performance firsthand. This approach helps ensure that the resins you consider will meet the specific demands of your projects.

Another critical factor to consider is the supplier's ability to provide consistent quality over time. Establish a dialogue with your potential suppliers to discuss their quality control processes and how they manage fluctuations in raw material availability. Understanding their production processes and lead times can greatly influence your project's timeline and overall success. Partnering with suppliers who are transparent about their operations and who can demonstrate a commitment to consistency will ultimately contribute to the durability and effectiveness of your final product. Making informed decisions at this stage can save time, reduce costs, and enhance the overall quality of your projects.

Related Posts

-

Unlocking the Advantages of High Performance Polymers for Enhanced Durability and Efficiency

-

Crafting Excellence: The Superior Quality of China's Best Coating Epoxy Resin for Global Industries

-

Ultimate Guide to Choosing the Best Industrial Epoxy Resin for Your Projects

-

Unleashing the Power of Best Resin Coating in Global Manufacturing Revolution

-

7 Essential Tips for Choosing the Best High Performance Plastic in Your Projects

-

China's Quality Revolution in Best High Performance Plastic for Global Buyers

100% Mercury Free

All of Hapco's formulations are completely free of Mercury.

50 Year Track Record

Hapco has been in business for over 50 years!

*NOTICE* Hapco will be will be closed on Monday, May 26th, in observance of Memorial Day. |

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |